How much should a procurement process vary by company or category?

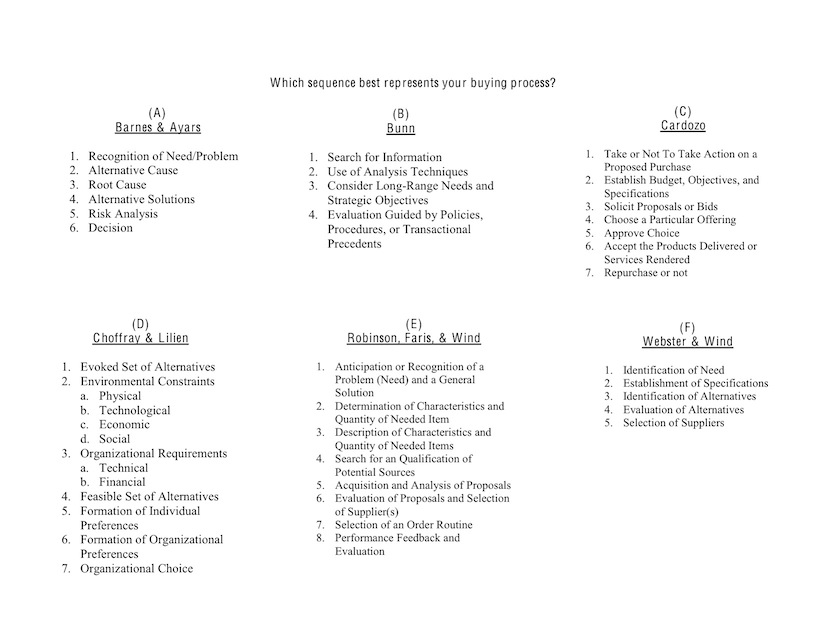

Last week I shared six B2B buying processes being compared by Wake Forest University in North Carolina. You can learn more about their research here.

I looked at the processes, and can see where each of them would have a place in the right scenario. You would expect processes to be different by company or industry, but do you ever vary your process by category? Feel free to share you comments below or join the conversation on Twitter: @BuyersMeetPoint.

I think (E) Robinson, Faris, and Wind most closely resembles the standard strategic sourcing process that most organizations follow. A typical process usually 6-8 steps, starting with internal and historical data collection and leading to either supplier performance management or a hand-off to the internal stakeholders who will manage the relationship for the duration of the contract.

That being said, the other models match different (and maybe less typical but no less common in the grand scheme of things) procurement situations...

(A) Barnes and Ayars: Strikes me as being very demand management conscious. All of the investment in understanding root and alternative causes after identifying the need but before making a decision suggests to me that if the need is proven to be justified, it is less important who is selected as the supplier.

(B) Bunn: Feels more like an ongoing or long term category management strategy than a process that would lead to the selection of a supplier and the signing of a contract.

(C) Cardozo: This process is interesting because it results in a test cycle rather than a contract. It might be appropriate in a capital equipment purchase that is for one need or location but which might be repeated in the future at another site.

(D) Choffray and Lilien: Reads like the process I might use if I were selecting a third party service provider for a strategic outsourcing deal. The up front, detailed investment in understanding constraints and requirements sounds like a self-discovery process, where the final decision will be based more on internal circumstances (and perhaps some early change management) than market forces.

(F) Webster and Wind: Reads like a decision based on cost rather than more value added components. It isn't just the brevity of the process that makes me think this, but also the fact that it goes straight to selection rather than evaluation of suppliers.

When you subscribe to the blog, we will send you an e-mail when there are new updates on the site so you wouldn't miss them.